Technical Articles

Information flow on the shop floor: closing the gap with wireless technology

Material flow made transparent – also for non-inventory-managed items. A wireless-based automated material requisition system (AMS) provides the solution and can also be used for other intralogistics tasks.

Source: etz (S4/2025)

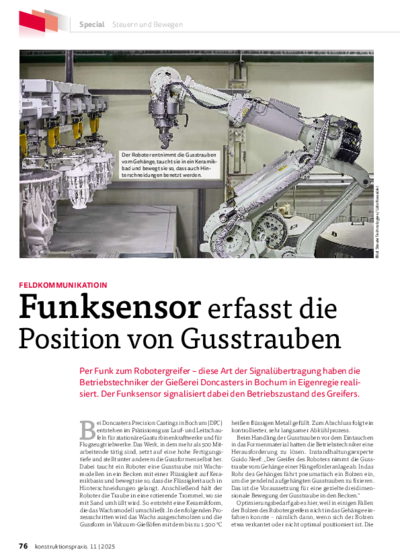

Wireless sensor detects positions of clusters

Wireless connection to a robot gripper – the industrial engineers at Doncasters in Bochum have single-handedly realised this type of signal transmission. The wireless sensor signals the operational status of the gripper.

Source: konstruktionspraxis (11/2025)

Sensors now smart and wireless – New generation of wireless sensors with optimised power consumption and installation flexibility

Cabled sensors reach their limits in many applications involving robotics, toolmaking, mould design or handling technology. Wireless sensors can provide a flexible alternative – especially when they are self-calibrating with minimum energy input. A new sensor generation shows how this technology has developed, and which application fields it is opening up.

Source: A&D (11/2025)

Non-contact is better – Machine safety in dust Ex zones

Safety switches used in explosive environments have to meet two different complex sets of requirements: those for explosion protection, and those for machine safety. Engineers have the choice between different designs and different active principles. At the Powtech, the steute business division Controltec will be demonstrating the various available technologies – one of which plays a particularly prominent role.

Source: CITplus (09/2025)

Keep on running… – Heavy-duty switchgear at the POWTECH TECHNOPHARM

Belt misalignment, belt rips or danger to persons: bulk goods conveyor systems harbour multiple potential risks that users should be aware of. At the POWTECH, steute will be showing highly efficient solutions and beneficial innovations.

Source: SCHÜTTGUT & PROZESS (04/2025)

Industrial Wireless for retrofit projects – Switches and sensors made easy

The greatest effort required when installing e.g. position switches or sensors on (already) existing machines is usually the laying of power and signalling cables. Read on to find out how wireless switching devices can make this task a great deal simpler.

Source: MY FACTORY (04/2025)

Robot-controlled tool construction for precision casting – Production of turbine blades

A wireless connection to a rotating robot gripper – the industrial engineers at Doncasters Precision Castings in Bochum have now single-handedly realised this type of signal transmission. Their chosen solution deploys a wireless sensor from steute: it signalises the operational status of a gripper which removes clusters from a suspension track. Here an overview of the technology.

Source: GIESSEREI (05/2025)

Mechanical, non-contact, wireless – Valve position monitoring for the hydrogen infrastructure

Setting up the hydrogen infrastructure – from the electrolyser to the distribution network to the consumer – requires both suitable valves and controls to monitor their positions.

Source: CHEMIE TECHNIK (05/2025)

Remote gripper control – Practicable alternative to cabled switching devices

Wireless switches and sensors have many benefits in the field of robotics, especially in conjunction with rapidly repeating three-dimensional movements. They are versatile and not subject to wear and tear. As a practicable alternative to cabled switching devices, the steute portfolio includes a tried-and-tested wireless system.

Source: INDUSTRIELLE AUTOMATION (01/2025)

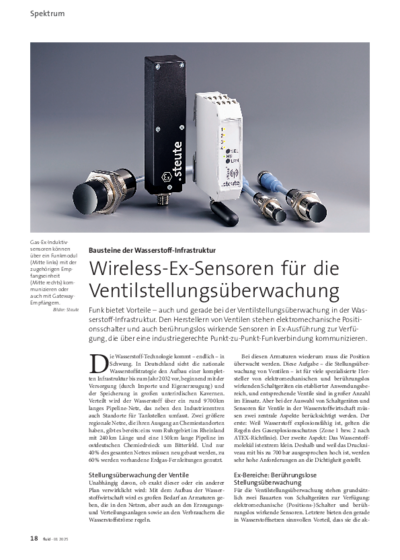

Wireless Ex sensors for valve position monitoring – Building the hydrogen infrastructure

Wireless solutions have many advantages – also and including for valve position monitoring within the hydrogen infrastructure. Valve manufacturers can choose between electromechanical position switches and non-contact sensors in Ex variants, which communicate via an industry-compatible point-to-point radio connection.

Source: fluid (01/2025)

Select the right valve position monitoring system - Switches and sensors for complex applications

Valve manufacturers have a wide choice when searching for suitable switching equipment to monitor valve positions. Different types of electromechanical switches and non-contact sensors are available, with series suited to explosive zones, corrosive environments and subzero applications. In many cases it can be beneficial to opt for wireless switches, including in Ex zones.

Source: CITplus (7-8/2024)

"Wireless Ex" sensors for valve position monitoring

Wireless has benefits – also and especially for valve position monitoring within the hydrogen infrastructure. Valve manufacturers have access to electromechanical position switches and non-contact sensors in Ex variants with industry-compatible point-to-point wireless communication.

Source: H2 compact (01/2024)