At the SOLIDS 2026, the steute business division Controltec will be presenting solutions for the safe and reliable operation of belt conveyors: emergency pull-wire switches designed for heavy-duty use; belt alignment switches in both conventional cabled variants and as a wireless system; and an easy-install belt rip detection system.

The ZS 92 S series of emergency pull-wire switches is well established in extraction and underground mining applications worldwide, for example tunnelling. They are flexible to install and cover hazardous distances of up to 200 metres – true to the principle: one pull on the wire, and the belt comes safely to a standstill. Construction features, such as multiple coatings of the robust die-cast aluminium enclosure, ensure uninterrupted operation even in adverse environmental conditions. And the option of special multiflex wire guides means that even non-linear hazardous areas can be safeguarded.

The same robust enclosure series is the basis for the ZS 92 SR belt alignment switch. Its actuator lever detects any misalignment caused by uneven loading of the belt. In such cases, the switch triggers – depending on its integration in the control system – either a stop of the conveyor or a correction of the belt alignment. This reliably prevents the dropping of conveyed material and/or a standstill involving laborious restarting.

A new addition to the heavy-duty range of steute switching devices for conveyor technology is a wireless variant of the belt alignment switch. It uses the sWave wireless technology developed by steute specifically for industrial applications. It has clear advantages, especially for extraction operations, because no costly cabling is necessary. In addition, cables from e.g. machinery cannot be driven over and damaged. First applications, including at a gravel works, have confirmed the suitability of the wireless switching system for daily use in ranges of up to 400 metres. steute has also developed an outdoor antenna especially for such uses.

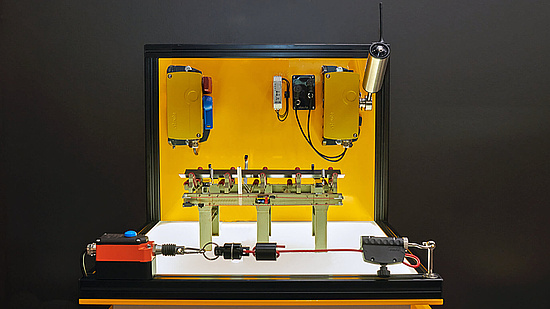

A further measure to guarantee the fail-safety of belt conveyors is provided by a belt rip detection system – new to the steute range and based on the pull-wire switch principle. A wire is installed just below and perpendicular to the conveyor belt, its tensioning monitored by a compact ZS 71 pull-wire switch.

If bulk material or a foreign body should penetrate the belt and continue moving along with the belt, then the wire deflects. This triggers the pull-wire switch, which sends a signal to the control system, in turn causing the conveyor to stop immediately, preventing any further damage. A miniaturised safety decoupler separates the switch from the wire system. Depending on the surroundings, monitoring is performed with one system (two deflections) or with two systems mounted in parallel (one deflection each).

All four switching, safety and monitoring systems – emergency pull-wire switch, cabled and wireless belt alignment switches, and belt rip detection system – will be exhibited on a belt conveyor model live in Dortmund.

steute at the SOLIDS 2026: Hall 5, Booth 5-Q32